af contributor |lethbridge

One machine has totally changed Brian Stoutjesdyk’s manure handling.

The Coaldale dairy farmer says a $100,000 system that separates solids from liquids in manure slurry – creating high-quality bedding and a liquid manure that is less costly to apply – has been a great investment.

As in most dairy farms, a continuous hydraulic scraper cleans manure from the alley between the bedded areas of the loose-housing barn into the pit below. Once a day, the slurry is pumped through a fan separator that uses screens and a screw press to extrude dry solids from the manure and returns the liquid to the slurry tank. The light and fluffy dry solids fall onto a belt that carries them out of the barn.

Read Also

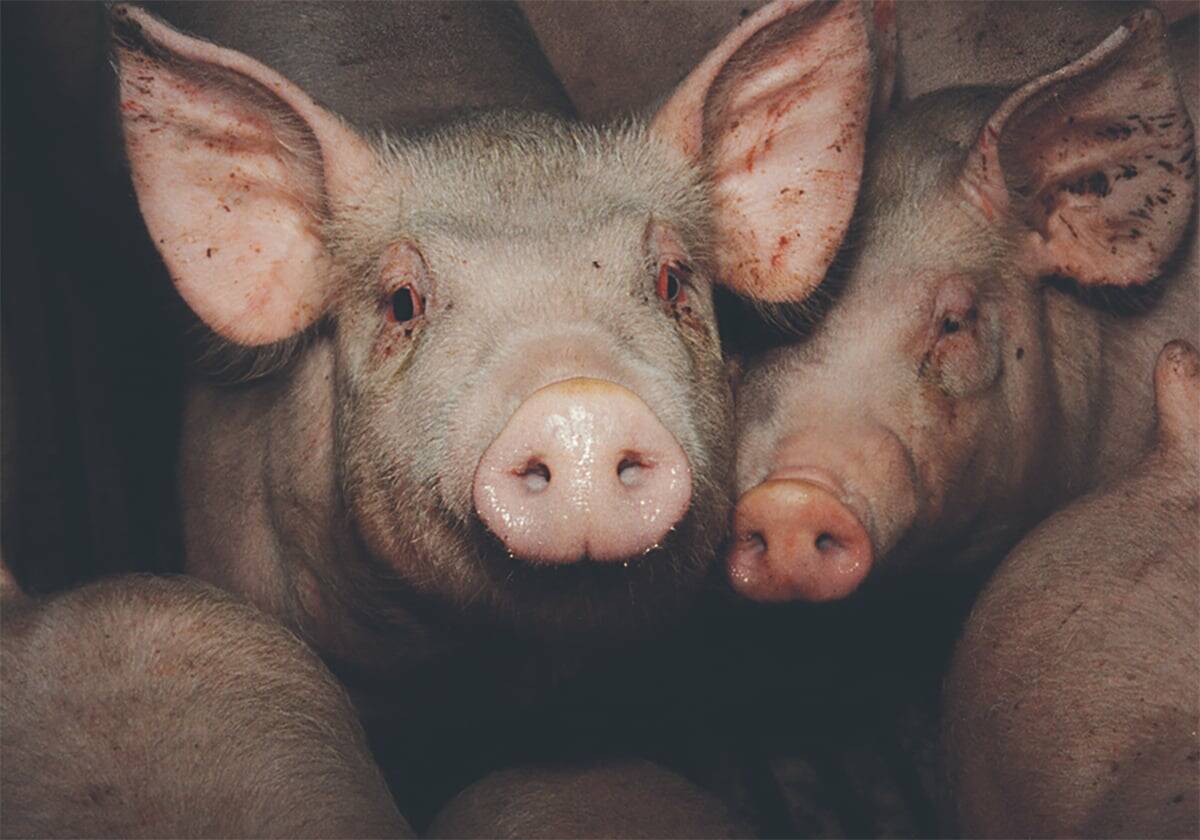

Scientists discover cause of pig ear necrosis

After years of research, a University of Saskatchewan research team has discovered new information about pig ear necrosis and how to control it.

The dry solids look much like silage and have no noticeable odour. Stoutjesdyk uses it for bedding the milking herd in the barn as well as for the young stock and dry cows outside. The milking cows are Stoutjesdyk’s main concern.

“They seem quite happy with the new bedding,” he says. “We haven’t noticed any change from when we used sawdust. We haven’t had any health issues. That was something we were quite concerned about.”

It works well for his other cattle, too.

“The outside cattle seem to really enjoy the piles of dry manure solids. I think it’s probably like the manure piles in feedlots, it composts in place and gives off heat, so it’s a warm place for them to lie,” he says.

Selling surplus

The solids extracted from the manure from the 140 milking cows are enough to bed 1,000 animals, according to Stoutjesdyk. He’s only using about a third of the material and selling some of his surplus, but he’s planning to compost the solids and either market it to gardeners or use it on farmland.

“This stuff would be great for crops, especially zero-tilled land – you’d never see it in the stubble,” he says. “It’s easy to transport and spread, so we can take the product further and deliver phosphate to cropland at lower cost and, because it’s such a light product, there’s not the soil compaction you get spreading slurry.”

Stoutjesdyk intends to use the liquid on his own crops. He’ll mix about one part manure liquids with three parts irrigation water to fertigate crops. Much of the liquid will go on his corn, which can use the high nutrient levels in the liquids.

The $100,000 cost covers the whole manure separation system, and the Growing Forward program will cover half of that. But it pencils out even without the subsidy. Stoutjesdyk figures not having to buy sawdust for bedding will save him about $20,000 a year and he’ll save another $25,000 annually on hauling liquid manure. He’s also cut down his slurry storage needs by about 50 per cent.

The heart of the system is a fan separator made by a German company, which cost about $65,000. It takes about three hours to take the liquids out of the slurry from the pit. It uses a 10-horsepower electric motor and Stoutjesdyk can adjust the pressure on the system to modify the moisture content of the solids. He uses high pressure to produce dry bedding, but will likely leave more moisture for composting. The plumbing to connect the fan separator to the slurry pit was simple and Stoutjesdyk and his staff were able to do it themselves. He plans to put up a building to store the bedding as it tends to blow.

Even the savings on bedding would pay for the cost of the system in five years. But there are other benefits. There’s no need to add water to the slurry tank as sometimes happened when he used sawdust bedding. He also has easier, less costly ways to spread manure on his cropland, so he can justify spreading it on land further from home. There’s much less temptation to over-apply manure to some fields. Eventually, Stoutjesdyk would like to add a biodigester to his system. If he had a partner to manage it, the natural gas and carbon credits might make that economically feasible, too.

———

“Thisstuffwould begreatforcrops, especiallyzero-tilled land–you’dneversee itinthestubble.”

Brian

Stoutjesdyk