Controlled traffic farming has yet to catch on in a big way in Alberta, but it proved its worth during last year’s drought for a long-time practitioner.

“I grew canola and barley last year and we had 28-bushel canola on four and a half inches of rain and five weeks of smoking hot weather,” said Steve Larocque, an agronomist at Three Hills who has a small cropping operation. “Neighbouring fields were like 20 to 18. Dismal.”

In controlled traffic farming (CTF), all equipment is run on the same tracks, called tramlines, year after year. That limits compaction to just those tracks, improving water infiltration and soil health in the rest of the field.

Read Also

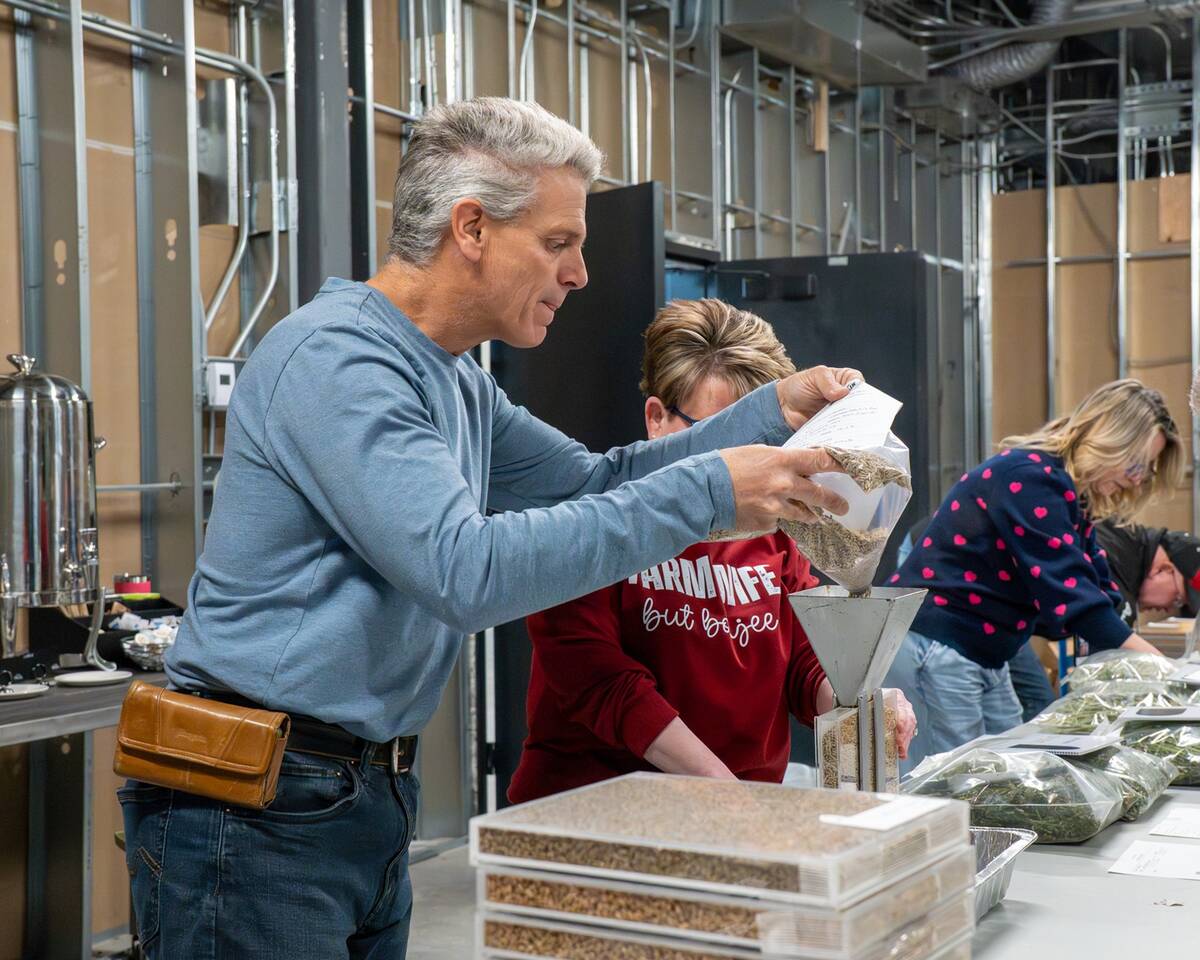

North American Seed Fair continuing a proud 129-year-old agricultural tradition

One of North America’s longest continually lasting seed fairs makes its 129th appearance in southern Alberta.

Over the years, Larocque said his barley yields have increased eight per cent. However, the impact on his barley last year is unknown as he decided to apply a plant growth regulator after receiving four-and-one-half inches of rain in early June.

“On a drought year where CTF would have shined like it did in canola, I applied a plant growth regulator to my barley, which erased any benefits from CTF by adding a tonne of stress,” he said. “It was really unfortunate because I’ve been waiting 12 years to really test the system under drought conditions.”

There’s no secret about why non-compacted soil produces better crops, not only during drought but also in years with excessive moisture, he said.

“When you get average rains, everybody wins,” said Larocque. “But the whole premise of CTF is to allow that soil to breathe, to open up and repair itself over time. It adds a lot of aeration and porosity.”

Has Larocque had inquiries about CTF following last year’s drought?

“No, and one of the reasons I think is we fared really well financially because of crop insurance,” he said. “Crop insurance paid out.”

Although widely used in Australia, adoption of CTF has been slow in Alberta, said Larocque, who became an advocate of the practice after receiving a 2007 Nuffield scholarship and seeing it in action Down Under.

However, there is a significant learning curve involved and the not inconsiderable problem of having equipment align with the tramlines for both wheel spacing and equipment width. As well, there isn’t an immediate financial incentive to change, said Larocque.

“Why would you change when you’re making money?” he said. “People are taking baby steps.”

However, the benefits go beyond reducing overall compaction because tramlines allow farmers to start seeding or harvesting earlier when field conditions are wet. It makes in-crop applications easier and reduces fuel use and machinery wear.

“The best analogy is taking a bicycle and riding down a gravel road, and then riding down an asphalt road — and tell me what the resistance is like,” said Larocque. “Naturally, when you’re driving down CTF-hardened traffic lanes, you require less energy.”

If farmers are interested in converting their operations to the practice, Larocque recommends focusing on sprayers and combines to start because both machine tracks can be matched. Appropriate GPS technology is required.

“You can start up by just running tramlines on your sprayer, and you can tiptoe your way into it. You don’t have to go all in,” he said. “In many cases, it’s a gradual process and something that you move towards.

“So start with your sprayer, maybe add in your combine, and get your logistical head wrapped around it. A lot of times we are our own worst enemy — we can think of a million reasons why it won’t work.”

Grain carts are one of the worst soil compaction offenders, said Larocque, noting machine speed and weight add to compaction. But grain carts can be run on tramlines despite farmers thinking it’s more challenging, he said.

“The weight you add and the faster you travel, the bigger the wave, the harder it is,” he said. “So, the grain cart is logistically challenging. On big fields a lot of times they’ll just split a field in half and have a turnaround, so you don’t have to go all the way down to the end. Split a half section into quarters — which most farmers do anyway — when you’re blocking it out.”

Controlled traffic farming is a good way to dramatically reduce input costs (including fuel, time, and machinery wear) while increasing yields and profitability, says the National Institute of Agricultural Botany in the United Kingdom.

“Some farmers in Australia have cut their machinery costs by as much as 75 per cent while their crop yields have risen,” says the organization on its website.

Getting into fields because they absorb moisture — be it spring snow melt or fall rain — can also have a big impact on the bottom line, added Larocque.

“I don’t know how you put a value on timeliness, but it’s big,” he said. “We can travel down fields much sooner and much easier.”

Can CTF take off in Canadian agriculture?

“Certainly, in drier areas. I’d be all over it if I were in a drier area,” said Larocque. “As soon as you get further east, like east of Drumheller all the way to the border – anywhere you really need to have resilience, whether it be floods or droughts, that’s where CTF shines.”

Scott Keller, who farms wheat, barley, canola, peas, fava beans, oats and winter wheat near Camrose, is another CTF practitioner and advocate. He has been using zero till since the 1990s and said with good quality GPS, CTF is the next step.

“One of the important things with CTF is to get down to that repeatability of trafficking,” said Keller, who began transitioning in 2014.

The process of switching equipment took several years but the effort was worth it, he said. Being able to work in wet conditions can be invaluable, said Keller.

“We’ve had situations where it’s time to spray, but normally the field would be too wet. But with tramlines set up, it’s amazing how the sprayer sits up on those tramlines and doesn’t cut ruts.”

Grain farming equipment will likely keep getting bigger, said Keller, so CTF could become more relevant as compaction becomes a bigger problem.

“And the other beauty is, when we do make ruts, they’re all in the same spot,” he said. “Even if you don’t think there is a benefit to doing CTF, start setting up sprayer tramlines and you’ll see it for yourself.”