You can lose a lot of money in a hurry, so watch for potential canola storage problems as fall transitions into early winter, says a provincial crop specialist.

“Canola seed’s high oil content makes it very susceptible to deterioration in storage,” said Neil Whatley. “Safe, long-term canola storage is at or below eight per cent moisture content and cooler than 15 C. Declining outside air temperatures also need to be properly dealt with to ensure safe storage.”

Canola respires or goes through a ‘sweat’ period for up to six weeks after being binned.

Read Also

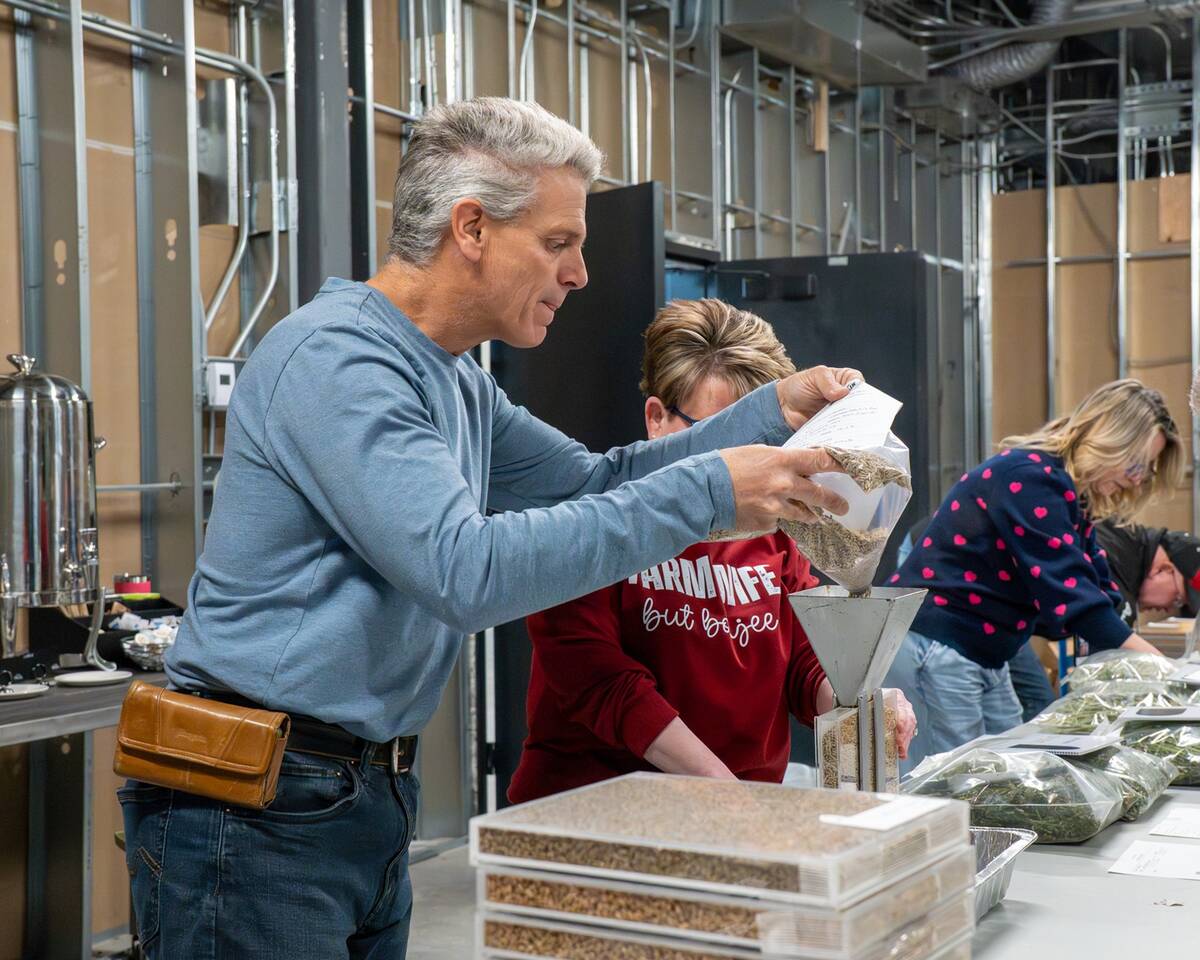

North American Seed Fair continuing a proud 129-year-old agricultural tradition

One of North America’s longest continually lasting seed fairs makes its 129th appearance in southern Alberta.

“Even if it’s initially binned dry, canola should continue to be monitored,” said Whatley. “Respiring canola generates additional heat and moisture, creating an unstable condition. This instability can potentially result in hot spots or mould growth, and when mould begins to form, it creates more heat that accelerates the spread of more mould growth.”

But spoilage can be eliminated if the canola is sufficiently conditioned to the point where the aeration cooling front moves entirely through to the top of the grain mass, he said.

Changing outside air temperatures in the spring and fall cause repeated moisture cycles in a bin, permitting moisture to concentrate in certain bin areas, and potentially leading to spoilage and heating. As outside air temperatures decline during October and November, the grain nearest to the outside bin edges cools first. This cooling system then migrates downward along the bin edge, and then upward through the central core.

“As this cooling system migrates, it gathers moisture and warmth that creates a pocket of humid and warmer air at the top of the central grain core where spoilage and heating can begin,” said Whatley. “So as outside air temperatures decline, aeration fans should be operated again until canola at the top of the bin is cooled to the average daily temperature.”

It’s wise to aerate repeatedly until the whole bin of canola is between 0 C and 5 C.

“November is an important month to check canola bins again to see if they are stable going into winter as temperatures drop below 0 C and stay there.”

Producers may also consider turning one-third of the canola bulk out of a full bin by truck in November.

“Moving the grain disrupts the moisture cycle created by declining outside temperatures, cooling the grain mass and reducing the risk of spoilage,” said Whatley. “Even if bin temperature is being monitored with sensors, this may not provide a complete reading of the whole bin as problems may emerge in pockets away from the sensors.

“So turning the grain ensures cooling as well as allowing producers to smell the grain as they are moving it to let them know if any grain is in the first stages of spoilage. If green counts, moisture, weeds or dockage are high, turning the whole bin may be safest.”

The risk of spoilage increases if there is more green seed as it has a higher moisture content.

“Such canola should be delivered as soon as possible to prevent spoilage, which could result in further price reduction. Extra attentiveness is also required when canola is stored in large bins, especially tall and narrow bin types that can reduce aeration airflow due to increased compaction.”