Sugar beet growers have been in the “hurry up and wait mode” this fall, constantly watching their computers for emails from the sugar factory telling them they can harvest for a few days. The growers had barely started harvest of one of their best crops ever when an early-October blizzard took temperatures well below freezing, damaging the crowns of the beets. If the beets are put into storage, the damaged crowns rot, the juice runs out and heats that area of the beet pile, ruining sound as well as damaged beets.

Read Also

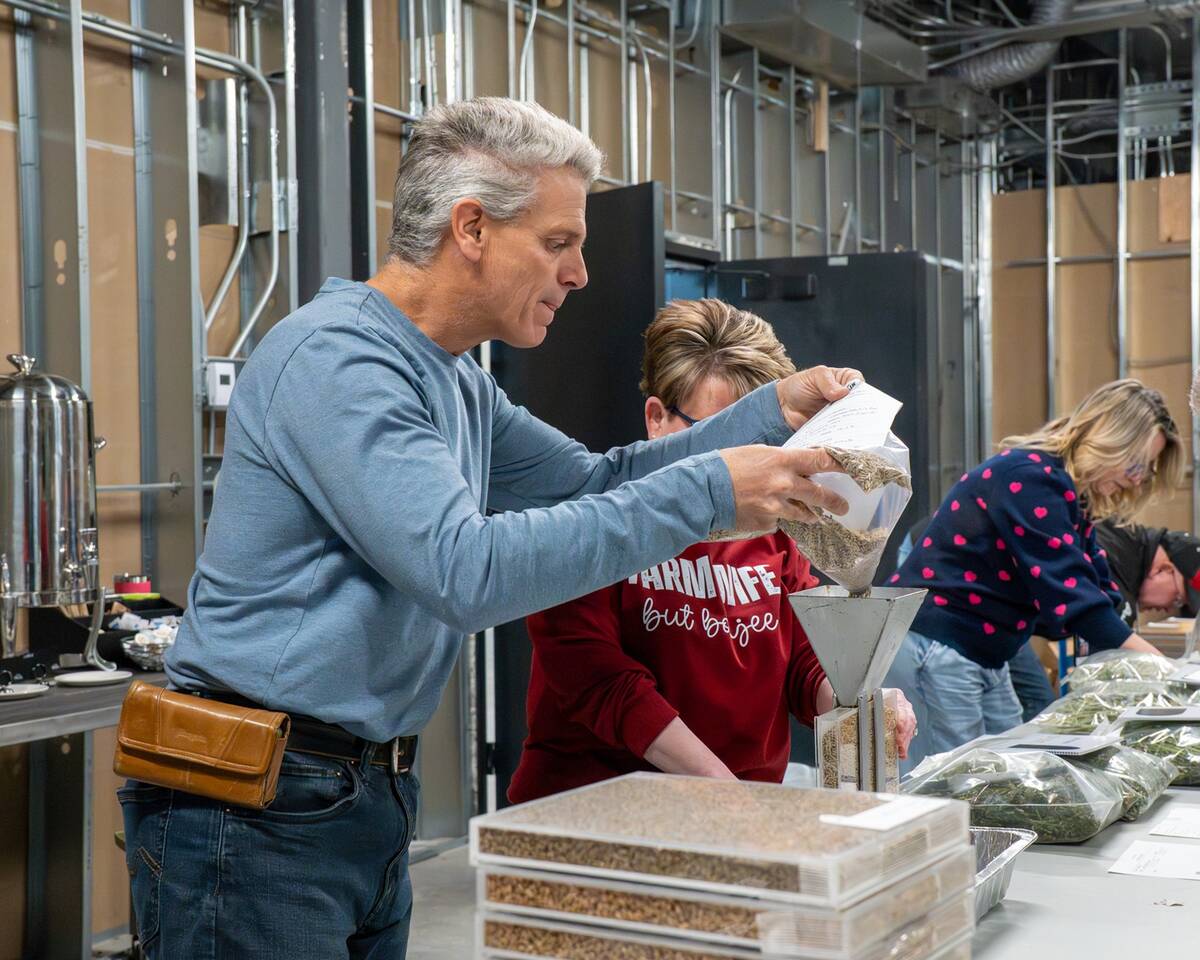

North American Seed Fair continuing a proud 129-year-old agricultural tradition

One of North America’s longest continually lasting seed fairs makes its 129th appearance in southern Alberta.

The damaged beets can be stored, but only for about two weeks instead of most of the year, as they can normally be stored. So farmers can only harvest and deliver as many beets as can be processed in 14 days.

“The beets are better off in the field,” says Andrew Llewelyn-Jones, agronomist for Lantic Sugar in Taber. “We hope we can get most of them, but we’re in the hands of the weather.”

The factory is working frantically to slice beets as fast as possible and take the sugar extraction process to a point where the juice can be stored. The first challenge is to keep frozen leaf ribs out of the factory machinery.

“Tops are a major issue for us,” says Llewelyn-Jones. “The leaf ribs are just like rope, wrapping around paddles and rods in the equipment and they’re terrible to get off. That slows us down, so farmers have to get rid of the tops. We have to reject any loads with top material – if the factory is slowed down, all the growers suffer.”

It’s taking some farmers three and four trips across the field to get rid of tops. Beet growers use a defoliator, which pulverizes leaves with flails, and follow that with a knife that slices the top off the beets. Staff at the plant are working from their own experience in 2002, when severe cold in mid-October led to the loss of beets. They’re also staying in touch with U. S. companies struggling with similar problems.

Regular emails keep growers aware of progress, but it’s tough to have most fall work done and be forced to leave beets in the ground. Growers have been harvesting on a quota – a tonnage based on their contract that they can bring in each week to share around the pain.

“Every week the weather allows us helps us get more beets in, but it will be a tall order to get them all,” says Llewelyn-Jones. “We took in 70,000 tonnes in the last couple of weeks, but there’s a lot more still in the ground. Beet quality isn’t the greatest, but we’ve been able to keep extracting.”

Estimates are that 200,000 tonnes were harvested in good shape before the cold snap. But perhaps 300,000 tonnes more had to stay in the ground while the factory worked on 40,000 to 50,000 tonnes delivered immediately after the bad weather. Beets that aren’t harvested by freeze-up will just be composted or fed to cattle.

The Alberta sugar industry is unique in the co-operation between growers and the sugar company. They depend on each other and growers are paid on the basis of tonnage and extractable sugar content. The year has some effect but sugar content is mostly a result of management of weeds, nitrogen and water. Farmers receive a bonus for higher-than-average sugar and a penalty for low levels.