Most producers are well aware of the risks posed by farm chemicals and take the necessary precautions.

But are you always aware of the risks from some of a farm’s most common contaminants — simple dust and mould?

If so, you might want to keep that N95 mask handy even though COVID-19 mandates are being lifted, says a leading specialist in occupational medicine.

Dust is sneaky, said Dr. Niels Koehncke of the Canadian Centre for Health and Safety in Agriculture at USask.

Usually, the dust you can see — the kind that gives objects a dirty appearance — is handled easily by the respiratory system. However, the smaller the particles, the more easily they can be inhaled into the lungs and create health problems.

“The one that immediately jumps to mind is grain dust,” said Koehncke. “But even in animal production, the mixture of dried feed, manure and even soil all mixed together can result in very small particles that can be inhaled, especially if they are very dry.

“They can create mould and fungal contamination that can potentially present a risk.”

Although masks and other personal protective equipment (PPE) can make a difference, they’re not the be-all and end-all. More important is finding ways to remove or limit exposure to them, something Koehncke calls the “hierarchy of control.”

“We all know more about masks than we did two years ago thanks to the pandemic,” he said. “But depending on the type of dust, there are a lot of steps you can take to protect yourself from inhaling contaminants before having to wear a mask. Potentially, you do those things and a mask becomes just an added layer of protection.”

Read Also

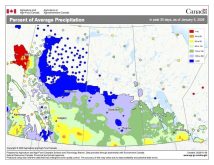

From winter soil to bountiful crops: Alberta’s ultra-early seeding experiment

Southern Alberta farmers are putting research into practice, pushing ahead traditional seeding times by months for spring wheat and durum.

Common health effects

The health effects of dust and mould are almost too many to count, said Koehncke. However, some of the most common symptoms include cough, phlegm and shortness of breath.

Exposure to mouldy grain, feed or hay can create non-specific symptoms such as headaches and poor appetite in addition to allergic reactions, asthma and airway or throat irritation. Rarer conditions include Organic Dust Toxic Syndrome (ODTS) and Farmer’s Lung.

ODTS (commonly referred to as ‘grain fever’) is a shorter-term condition caused by exposure to very high levels of organic dust and sometimes bacterial contamination in organic dust. Symptoms may include cough, fever, chills, fatigue, muscle pain and loss of appetite.

If those sound familiar, it’s because they’re the hallmarks of the flu, which it is commonly mistaken for. (Today, many of those symptoms may also point to COVID.) Fortunately, most people recover, without treatment, from ODTS within 36 hours.

“We don’t see it often clinically because not everyone gets help for it or mistakes it for the flu.”

Farmer’s Lung also produces flu-like symptoms but typically lasts longer and is a bit more serious, said Koehncke. It enters the body via inhalation of spores from mouldy hay, straw or grain.

“It can actually cause changes in the lungs that might improve over time if that exposure stops,” he said. “We don’t see it as often anymore — we’re not quite sure why. But it’s certainly still a risk.”

Dust and mould can be damaging for anyone but especially those who already have a respiratory health issue, said Koehncke.

“A lot of these dust and particles can certainly aggravate existing conditions like asthma, COPD (chronic obstructive pulmonary disease) or bronchitis and make things worse.”

The hierarchy of controls

Think of it as an inverted pyramid with elimination (physically removing the hazard) at the top and PPE at the bottom. The actions in between include substitution (replacing the hazard), engineering controls (isolating people from the hazard) and administrative controls (changing the way people work).

An example of eliminating a hazard would be identifying areas with a lot of dust and cleaning those areas. An administrative control might mean storing grain at recommended moisture content levels to reduce the growth of mould spores.

“Maybe there’s a ventilation system or local exhaust vacuum or fan to blow (contaminants) away from where you’re breathing,” said Koehncke.

If these or other controls aren’t sufficiently effective, it’s then time to combine them with masks and other PPE units, he said. (This is not to say that PPE should not be worn during the previous steps — the hierarchy is simply an illustration of effectiveness.)

Right mask, right job, right fit

This can vary according to the individual and situation, but should always follow three fundamental rules: Use the right PPE with the right fit and the right ventilation for the job you’re doing.

The first thing to know about masks in ag settings is that one-strap masks, cloth face coverings and the now-famous surgical mask simply don’t cut it.

Surgical masks are useful when it comes to transmission of airborne aerosols or droplets containing viruses, but they’re not robust enough for farm work.

For work masks, discussion usually starts with N95s. These circular masks are considered ideal for cleaning out grain bins, working with hay or in dusty livestock buildings, to name a few examples. They can even be used for pesticide handling if the product label specifies it.

“There’s a lot of attention on typical two-strap masks today but N95s are an option in agricultural settings,” said Koehncke. “They’re a much better form of protection; they fit more snugly and may provide that added layer of filtration.

“They have particulate filters. They do the job against all those dusts we’re talking about and work against mould. They even work against welding fumes. And as we’ve learned, they work against viruses.”

For those wishing to take protection to the next level, some respirators — such as half-face and full-face reusable respirators — have replaceable filters and cartridges which protect against organic dusts (such as grain, feed, and hay), pesticides, paints and paint fumes, disinfectants, cleaning chemicals and anhydrous ammonia.

“It has to be the right type of mask and the right type of filter for what it is you’re working with,” said Koehncke. “That will go a long way to protecting the lungs and reducing the risk.”

As a general rule, the greater the protection, the greater the cash outlay. Powered Air-Purifying Respirators (PAPR) and Self-Contained Breathing Apparatus (SCBA) units may even require training for effective use.

Masks and respirators should be kept somewhere you can access them easily when needed, said Koehncke.

“Don’t be frugal with them — have one available. I keep one around because it’s sometimes unpredictable when some of these exposures might happen or when you might be working around dust that just comes up unexpectedly.”

It’s crucial that masks and respirators fit snugly in order to do their job effectively.

“If it’s not sealed well — (and) the air leaks around the edges and past your cheeks — it defeats the purpose of the filter. It’s like having your furnace filter with a big hole in it.”

But they also have to be comfortable.

“If it’s not comfortable or it’s too tight or you sweat too much in it, it’s not going to get worn. Finding a mask that is comfortable for someone to wear as long as they need to is important.”

For a deeper dive, a booklet called Save Your Breath: Respiratory Health in Agriculture (PDF) is online.