A Dutch firm says its first advanced automated cold storage warehouse in Canada is getting closer to completion, and will revolutionize the southern Alberta agriculture corridor by boosting sustainability in the supply chain.

NewCold’s $222 million state-of-the-art food storage facility in Coaldale’s industrial park is slated for a late-June opening date. The firm has 22 warehouses on three continents, offering a combined capacity of more than 1.5 million pallet positions.

Coaldale Mayor Jack Van Rijn was pleased with the relative speed in which NewCold agreed to open up shop in the southern Alberta community of more than 8,900 people, with other regions in Canada wanting to do similar projects.

Read Also

Alberta producers share why on-farm research drives success at RDAR showcase

Farmers explain how producer-led trials and strategic data collection are bridging the gap between the lab and the field in their operations.

“From the time we were first introduced to the executive of NewCold, it took 10 months… for them to be committed to the Town of Coaldale,” he said. “In comparison, they are trying to build one right now in Ontario and they’ve been at it for two-and-a-half years and they (hadn’t) even got to the development permit stage yet.”

Van Rijn made the comments at a ‘state of the region’ address in Taber earlier in 2025.

“It goes to show you through the guidance of our MLA Grant Hunter in red tape reduction in how we can move forward in getting a project the size of this in southern Alberta,” he said.

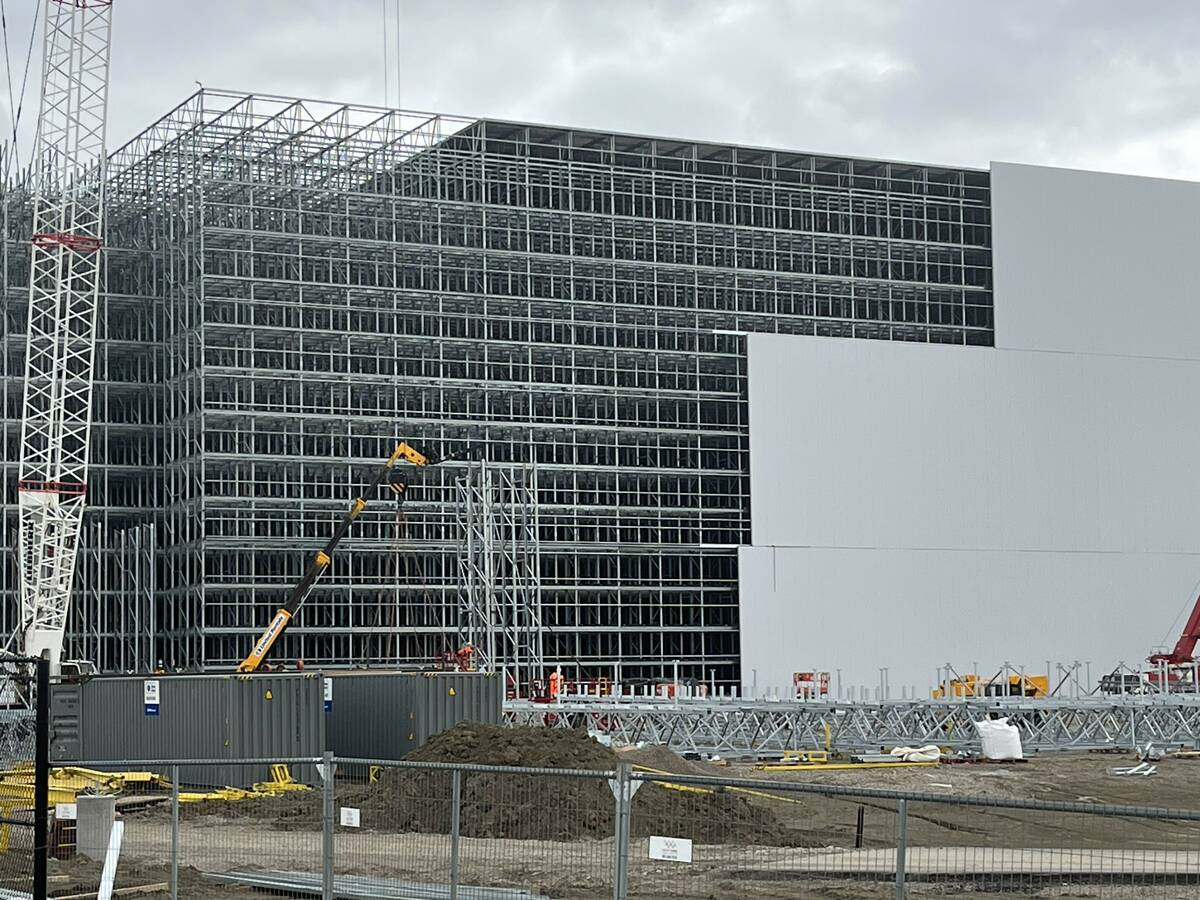

The facility will sit on 37 acres of Coaldale’s industrial park and is 320,000 square feet and 150 feet high. The cold storage facility has the capability of storing 56,000 pallets of frozen vegetables.

Van Rijn said in this case it will likely be frozen french fries, as a well-known producer of that commodity is said to be interested in leasing 100 per cent of the first phase.

The automated facility will be capable of loading or unloading a semi truck in six minutes or less without a human hand touching it. There have been 230 people building the facility, with an estimated 50-60 being employed when it becomes fully operational.

“This facility is inclined to reduce the carbon foot print associated with traditional cold storage. It uses 50 per cent less energy by employing cutting-edge insulation techniques and fully-automated processing,” said Van Rijn.

In getting the product out to global markets, NewCold, with financial assistance from the Alberta government, will partner with Coaldale to invest in the extension of Canadian Pacific Kansas City (CPKC) connectivity to the property, a necessity to reduce the environmental footprint, Van Rijn said.

The spur line to the NewCold facility is 2.6 kilometres long with costs of the $8 million project shared between NewCold and the Town of Coaldale 50/50. There is potential for other spur lines to come up in the Coaldale area if other industry comes calling. The spur line gives businesses ready access to export their products with ease and security either domestically or internationally. The investment will go into municipal rail lines to develop Coaldale into an export hub.

“The facility is a game changer for Coaldale and all of southern Alberta. This NewCold investment is the largest singular investment in the history of our community,” said Van Rijn. “We’re looking forward to the opening. This is only the first phase, the second phase is something they are very tight lipped about when it’s going to occur. This particular (phase) is 100 per cent leased out and they needed that commitment before they started entertaining the second phase. Our hope is that the construction teams will just stay there and keep building, but we don’t have any confirmation on that at this point.”