[UPDATED: Apr. 11, 2023] Canadian Rockies Hemp Corporation chief executive officer Aaron Barr says products are finally heading out the door of its plant in Bruderheim, Alta.

*The company began construction in 2019 and was ready to start processing about eight weeks ago.

“We ended up having about five months of extra additions to the plant to really get the throughput we wanted,” he said.

Read Also

North American Seed Fair continuing a proud 129-year-old agricultural tradition

One of North America’s longest continually lasting seed fairs makes its 129th appearance in southern Alberta.

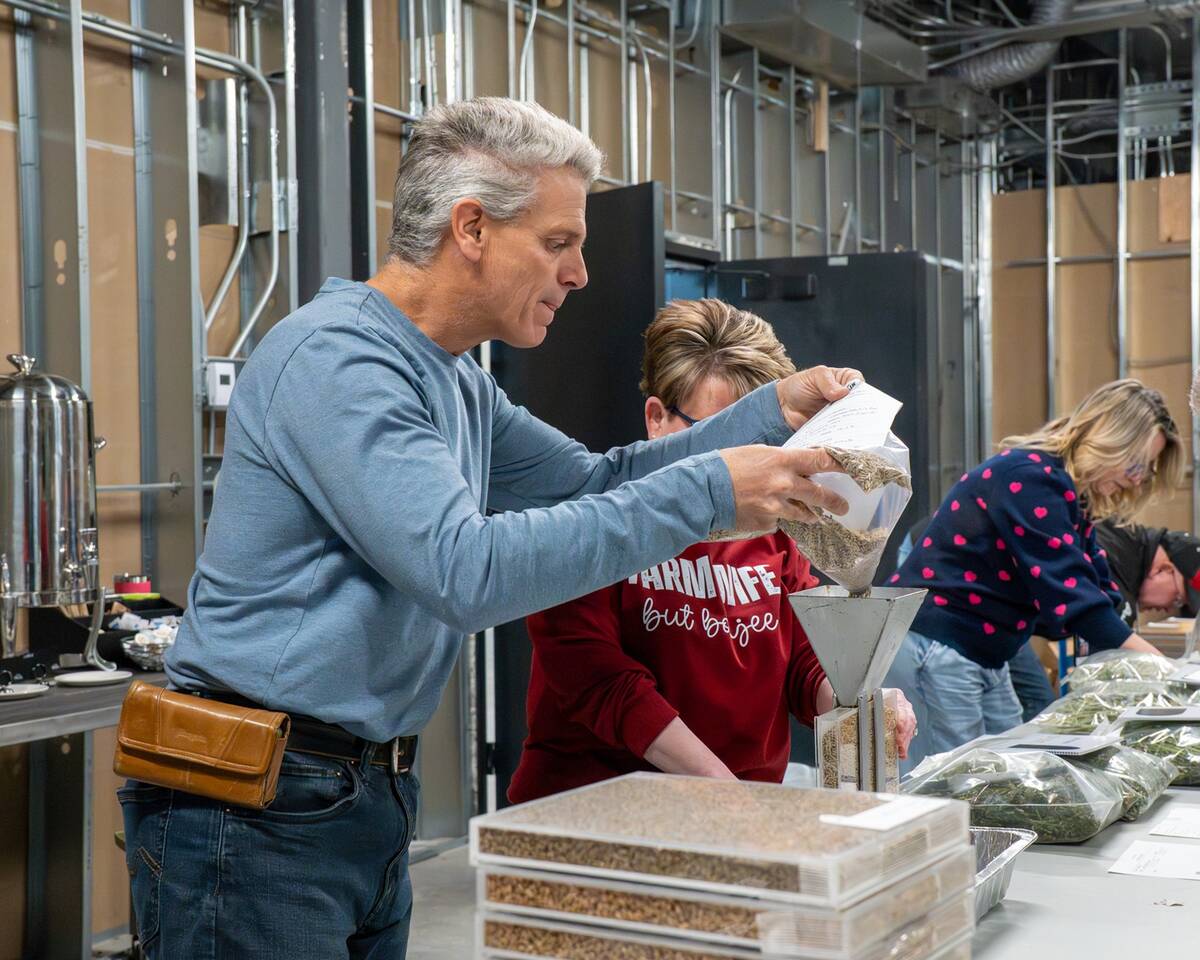

Canadian Rockies separates the hemp skin from the stalk, removing the fibre (bast) from the woody inner core (hurd). The fibre is processed into three different specifications for use in building materials, pulp and paper, and textiles. Screenings are sold for lower-end uses such as pellet fuel or cat litter.

The company processes 10,000 to 20,000 pounds of hemp a day. It has about 20 full-time employees and just started seven-day, 12-hour shifts.

“We’re hoping to go to a 24-hour shift by the end of April and we would be closer to 50 employees by then,” Barr said.

About 80 per cent of the products is exported to the United States.

The company contracts with growers within 150 kilometres of Bruderheim, including Athabasca, Lloydminster, Red Deer and Westlock. It had 25 growers in 2021 and 45 in 2022. It harvests the crop for the growers.

“This was our best year of growth yet on the fields. It wasn’t a total drought, not a total flood-out, it was what we consider a normal year. It’s nice to see average conditions on the field and we had some good yields. The farmers were all quite happy,” said Barr.

“We want to match our facility production with the number of growers we have so as we increase our plant production, we’ll contract more and more farmers. We’ve designed our plant to be able to process about 25,000 acres a year.

“In the past, we tried to go with more farmers doing smaller acres, to get comfortable with seeding hemp, and see how it goes.”

Barr said some growers started with 40 acres and are now growing 80.

“Now that farmers are comfortable with seeing the results of the crop and how it grows, we’re seeing farmers want to take on bigger field sizes. We’ll probably go with fewer farmers. We see it sitting very well with large grain farmers… They can seed more than they can harvest, because in our model you don’t have to harvest. There’s no combining, no bin drying, so those large grain farmers, this is where it fits with them. That’s where we are going to shift our focus.”

Barr said there’s increasing demand for sustainable biomaterials.

“With these big pushes coming out of Europe, which are now coming into Canada, people are thinking how to use more plant-based biomaterials and that’s why we’re seeing an increased demand. Now that we are able to establish a supply chain in Canada and North America, we’re seeing manufacturers have more confidence and be able to scale up hemp-based products.”

The consumer market

In Calgary, Hempalta is processing hemp into products for consumers.

General manager Brittany McKell said Hempalta buys hemp stalks, mostly from producers who have contracted with food manufacturers to grow the crop for seed.

The stalks are processed at the facility in Calgary and turned into products targeted for the high-end consumer goods market. Hempalta makes HempyCat, a high-absorption cat litter, HempZorb, a product for cleaning up spills, and Hempfreso, pads that can help prevent spoilage of fruits and vegetables. It also sells premium hemp animal bedding, which is used in the giraffe pen at the Calgary Zoo.

McKell said there are more than 25,000 commercial uses for industrial hemp and lots of opportunity for growth in the market.

“We are also looking to supply large volumes of our product streams to any other manufacturer who is looking to use hemp in their manufacturing, such as biofuel or biocomposites and textiles. If there is any other manufacturer who wants to use hemp in their formulation, we can supply it to them as well.

“Last year, a big portion of time was focused on rebranding a lot of products, refining our production co-ordination so we could understand what our supply needs were, and understanding our capabilities. The first year was getting us set up for a successful 2023.”

McKell said Hempalta buys hemp from southern Alberta farmers.

“We want to support our local markets as much as we can. Logistically, it’s a lot cheaper to source it if the farmer is in a three-hour radius from us.”

She said the company plans to scale up from processing one tonne of hemp an hour to four.

“We haven’t had any issues sourcing. There is plenty of hemp sitting out there. Starting this year, we’ll be able to contract a bunch of farmers.”

*Update: the year of construction was changed from 2021 to 2019.