Alberta is now home to an internationally certified laboratory for testing the radio frequency identification (RFID) tags used to track livestock across the value chain.

The lab, located at the Southern Alberta Institute of Technology’s (SAIT) Applied Research and Innovation Services (ARIS) department in Calgary, is one of only three certified animal RFID testing labs in the world and the only one in North America. It is also one of two labs capable of testing tags at temperatures of -35 C and below.

SAIT’s decision to seek International Committee for Animal Recording (ICAR) certification was driven by the Canadian Food Inspection Agency’s new testing framework which requires tags be tested in an ICAR-certified lab capable of testing tags at -35 C. This also allows animal tag manufacturers to certify locally rather than in Europe.

Read Also

Farming Smarter receives financial boost from Alberta government for potato research

Farming Smarter near Lethbridge got a boost to its research equipment, thanks to the Alberta government’s increase in funding for research associations.

This is important for the country’s animal traceability efforts, said Paul Laronde, tag and technology manager for the Canadian Cattle Identification Agency.

“In other parts of the world, they test tags at room temperature or a little below, and that’s fine, but in Canada we know producers apply tags in winter conditions,” he said.

“They leave tags out in their trucks in the winter and in some cases that could be -35 C or below. Tags are plastic for the most part and plastic loses elasticity the colder it gets so they become brittle, less flexible, and when you try to apply them it takes more force.”

Cold weather woes

An RFID tag works in conjunction with an RFID reader and each tag carries a globally unique number allowing the animal to be tracked from its point of origin to either its point of export or carcass inspection using the Canadian Livestock Tracking System database.

“A reader is essentially a box with an antenna connected to it,” said Laronde. “Inside the box is some circuitry that talks to the tag by sending out an electromagnetic wave that powers the tag up. The tag absorbs the energy and with that energy it sends back the unique number on its microchip.”

There is a regulatory approval process administered by the Canadian Cattle Identification Agency for cattle tags that takes place before tags can be sold to livestock operators. The SAIT lab is a part of this process.

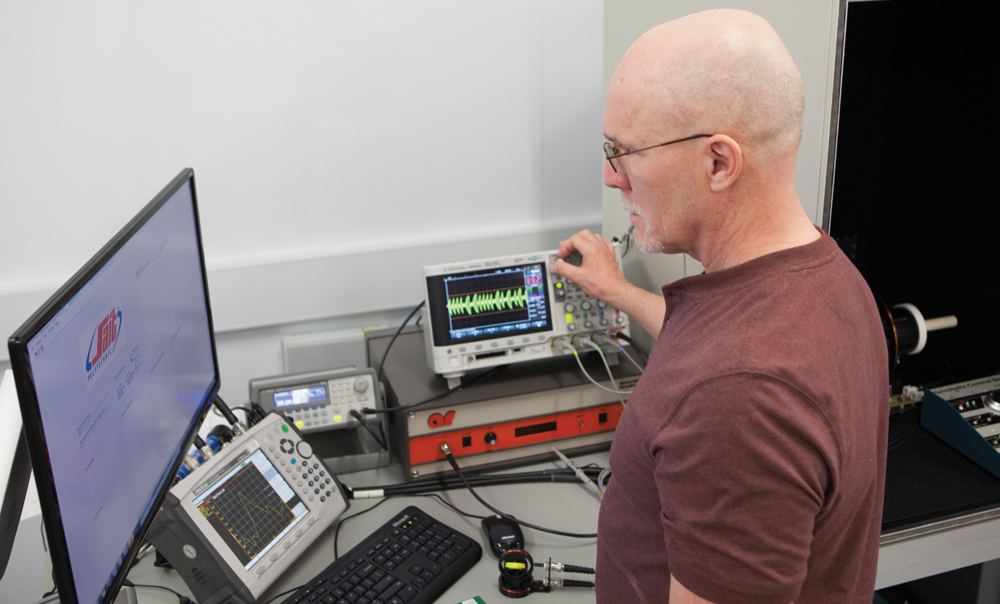

The lab looks at two main areas of tag functionality, said Bob Davies, project lead and quality manager with ARIS.

“One is electrical: Can we read the RFID part of the tag? There’s also the tag assembly — how it goes into the cow’s ear and how it stands up mechanically.”

A couple of things can go wrong in very cold weather, he said.

“One is they can come apart. The other is they just don’t apply very well. The tag is very brittle and the force required to apply the tag to the cow’s ear is very high,” said Davies.

“We test things like how much force is required to couple a tag together. We also take a look at the force required to decouple the tag. When the tag comes apart, it has to be very evident that it was used before. For example, the male part gets left inside the female part of the tag so it can’t be reused.”

Although tag failure is not common, when it does happen it can have a significant impact across the value chain, said Davies.

“If you have a failure rate of two per cent, you have to multiply that two per cent by the cost of tracing that animal back when it goes into the slaughterhouse without a tag. It’s significant enough for CFIA to implement its own framework for testing.”

Internationally certified

SAIT’s decision to become an RFID testing facility came about from discussions with the Canadian Cattle Identification Agency, CFIA, ICAR, Alberta Agriculture and Forestry, and the Alberta Livestock and Meat Agency.

“We were aware that tags had to go to Europe, which increases the time for getting samples over there and getting information back. It was also quite expensive,” said Laronde.

“Someone suggested that perhaps there should be one in Canada and that SAIT had an appropriate facility. The conversation started with them and there was interest. We decided they had the facilities, knowledge, and personnel to set the lab up to meet the ICAR standard.”

To receive ICAR accreditation, the test lab also had to be accredited by the International Standards Organization, which establishes worldwide standards. Armed with approximately $500,000 in funding from the Alberta Livestock and Meat Agency, SAIT proceeded to achieve ISO approval in 2012 and ICAR accreditation in February of this year.

“We turned this lab into a one-stop shop for CFIA’s required testing,” said Davies.