Give Barry Murchie just a few words to describe GoodLeaf Farms’ new Calgary-based farm facility and he’d probably say it’s a completely controlled vertically integrated operation that grows leafy greens, baby greens and microgreens.

Give the GoodLeaf president and CEO a few more words and he’ll call it a step forward in Canada’s food sovereignty.

“We create food sovereignty in a place and a portion of the supply chain where it doesn’t exist,” said Murchie.

Read Also

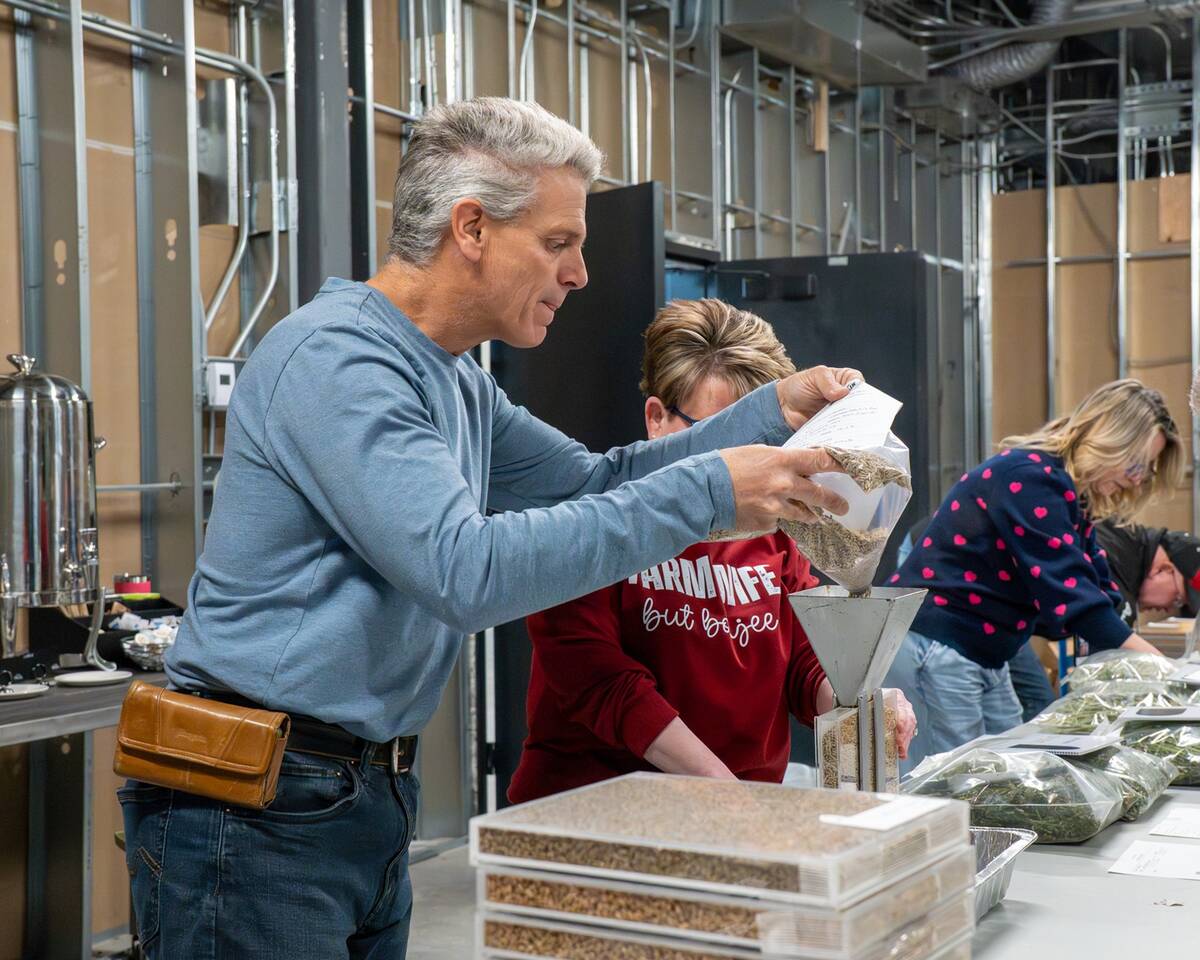

North American Seed Fair continuing a proud 129-year-old agricultural tradition

One of North America’s longest continually lasting seed fairs makes its 129th appearance in southern Alberta.

“Right now we’re dependent on California and Arizona for somewhere between 80 and 90 per cent of leafy greens. We’ve got massive food insecurity in this part of the supply chain.”

His business won’t have an effect on Canadian producers, he said.

“Think of it more as import substitution or import replacements. It’s very much a win-win for Canadians.”

The 96,000 square-foot facility at 108 Avenue Southeast in Calgary is GoodLeaf’s second Canadian location. It has its flagship commercial-scale farm in Guelph, Ont. A third farm is being built near Montreal with an expected opening in 2024.

Once fully operational (likely sometime in November), GoodLeaf Calgary is expected to produce more than two million pounds of leafy greens every year with 40 annual harvests of microgreens and 20 annual harvests of baby greens. These products will be found in grocery stores throughout Western Canada.

GoodLeaf’s plants are grown in a complex hydroponics system that provides nutrient-rich water. It mimics the effects of the spring sun with specialized LED lights that emulate red and blue wavelengths.

It’s important not to compare the facility to a greenhouse, said Murchie.

“In a greenhouse environment you have the ability to control a portion of Mother Nature but you’re still dependent on the sun and — depending on how many cloudy and colder days you get — it affects your crops, the quality, the growth cycle and all of the rest of it.”

In the case of vertical farming, every conceivable factor in the growth cycle is controlled without the use of pesticides, herbicides or fungicides. The indoor crops are immune to drought, heavy rain, frost or blizzards.

“In vertical farming, you take all of Mother Nature’s variants out of the equation. In the germination and growth cycle, we’re controlling the temperature, the humidity, the CO2 levels, the irrigation cycles, the nutrient loads, the air flow, the light recipe, the duration of light, the intensity of light, the light spectrum itself.”

Plants are grown with about five per cent of the water used in open field farming for similar products, which contributes to environmental sustainability.

“You end up with a cleaner, more nutrient-dense, fresher, longer shelf life, more visually appealing product that comes off in a very predictable way,” he said.

Most people are familiar with leafy greens and baby greens, but some might wonder about microgreens. According to Murchie, they’re packed with nutrients (up to 40 times the nutrient density of more mature plants, he said), medicinal properties and “explosive” flavour.

“Microgreens really can’t be grown in an outdoor environment. Think of them as almost immature plants. They grow so close to the ground and are so sensitive to the open environment that they just wouldn’t survive.”

However, they thrive in a controlled vertical farming environment, growing to maturity in a matter of days.

“We’re going from seed to package with microgreens in eight days,” said Murchie.

The benefits of microgreens are becoming more recognized, he said. For example, a component of broccoli microgreens called sulforaphane is known for its antitoxins and anti-inflammatories.

“There are some leading cancer institutes in Texas that have actually been on record to say that they’re seeing these medicinal properties being used in their patients.”

Murchie believes the elderly and athletes who seek high-nutrient food will be two major consumers of microgreens. The products may even be a solution to the age-old dilemma of kids refusing to eat their vegetables.

“Because of the flavour, we’re seeing kids starting to eat them as snack food,” he said.

“The micro peas are an example. They taste like something you’re getting from your garden. We’ve got lots of examples of parents that have introduced them to their kids and they eat them in place of what would have been unhealthy snack foods.”

Murchie says GoodLeaf’s baby green offerings (baby arugula, spinach, kale and lettuce) are pampered plants because they do not have to endure Mother Nature’s adversities. They also grow much faster than their open field counterparts.

“In an open field farming environment, you’re looking at 45 to 60 days to grow those crops,” said Murchie.

“We go from seed to package in 18 days. It’s a dramatic acceleration because effectively what we’re doing is creating an environment for the plant to thrive at every stage.”

GoodLeaf expects its products to reach store shelves in the second half of November. It has agreements with almost every major retail chain in Canada, plus a number of independents.

The success of its products in Ontario has made Murchie optimistic about expansion.

“We’re getting significantly faster traction on capacity commitments for the two new farms than we had anticipated. I think it’s a little premature for us to say with clarity when we’ll need to expand, but with one farm in Calgary servicing Alberta, the Prairies and B.C., the need for expansion is not very far away.”